Over the years I have been asked many times if the teachings of the Theory of Constraints apply to industries outside of manufacturing. Many of these questions have come from industries that were not manufacturing based and since TOC had its birth in manufacturing, it seems like a completely understandable question to port forth. The obvious answer for me to give is a definitive yes.....the teachings of TOC absolutely apply to any industry and to any system within any company. Let’s talk about why I believe this is true.

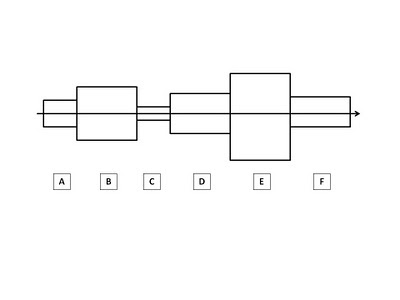

In its most basic form the Theory of Constraints teaches us that within any system there is one part of it, above everything else, that limits our ability to move closer to our goal (of making more money now and in the future). If our goal is more output, for example, then the secret to more output is to first identify the system constraint and then freeing up more capacity. In recent years I’ve been teaching this basic concept by relating it to a piping system used to deliver water from its input, through a series of pipes until the water reaches its output section as demonstrated in the drawing below.

The water enters the piping system through Section A, then passes through B and so on until it exits Section F. Clearly, because the diameter of Section C is the smallest, it totally controls the amount of water that flows through the entire system. It should be obvious that the only way to increase the output of water through this system is by increasing the diameter of the pipe in Section C. Likewise, increasing the diameter of pipes in any other section will not change the throughput of water through this system. In TOC terms, Section C is the system constraint. So how does this concept apply to other processes? Let’s look first at a manufacturing system and then relate it so other systems outside manufacturing.

Suppose in the drawing below we were producing high quality cannons. Maybe in Step 1 we were setting up a grinding operation and performed a rough grind to get it into the approximate final shape and this took 1 day to complete. In Step 2, suppose we had some kind of precision boring operation that required intricate details and it took 17 days on average to complete. Maybe Step 3 was a semi-finishing step and it took 5 days to complete and then Step 4 was a finishing step that required 2 days. Theoretically this process for producing cannons took 25 total days, from start to finish, to complete.

Using the same thought processes as the piping diagram, Step 2 of this process is the system constraint, only in this example, the variable is time to complete and not the physical diameter. And like the piping diagram, if you wanted more throughput of cannons, the only way you could do so would be to reduce the time required in Step 2. What if, for example, your market requirement was 1 cannon every 10 days? Without any changes to the constraint, you simply would not be able to meet the needs of this market demand simply because your capacity to supply cannons is 1 cannon every 17 days. So does it make sense that in order for the cannon process to meet these new market needs, you would need to focus on Step 2 and somehow eliminate the extra 7 days? Let’s look at a completely different type process and see if these same TOC basics apply.

Suppose we were looking at a basic purchasing process where we receive a request to purchase a part, order it, wait for the purchased product to arrive, receive it and finally deliver it to the requestor. Once again, using the same logic as the piping diagram, we identify that Step 2, because it takes the longest amount of time (i.e. 8 days), is the system constraint.

If we wanted to “speed up” this process, doesn’t it make sense that we would have to focus any improvement efforts on Step 2? I’m certain that Step 2 is full of wasted steps and that by eliminating or significantly reducing much of this wasted effort, we could improve the throughput of purchase orders through this process. In fact, if we wanted to significantly improve this process, focusing on Steps 1, 3 and 4 would yield little improvement.

The point is, no matter what type of system you are working in, the basics of TOC apply. That is, Goldratt’s five focusing steps always yield the most improvements. It doesn’t matter if you are working in a hospital emergency room environment, a scheduled maintenance environment, a food supply business, a retail operation, or even a military installation, TOC will always help you improve your business as long as you follow these five steps:

1. Identify the system constraint.

2. Decide how to exploit the constraint.

3. Subordinate everything else to system constraint.

4. If necessary, elevate the constraint.

5. Return to Step 1.

So the answer to the original question of whether TOC applies to non-manufacturing environments is a resounding yes!

Bob Sproull

No comments:

Post a Comment